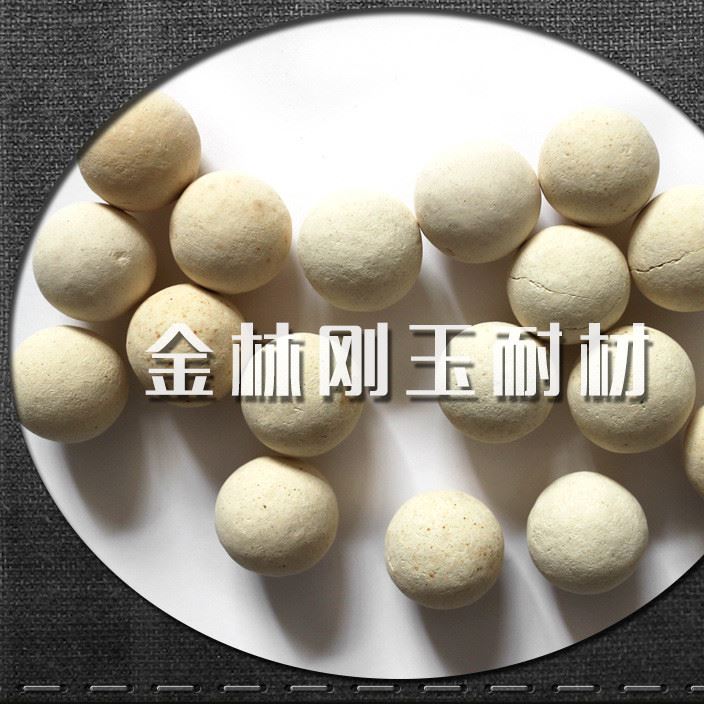

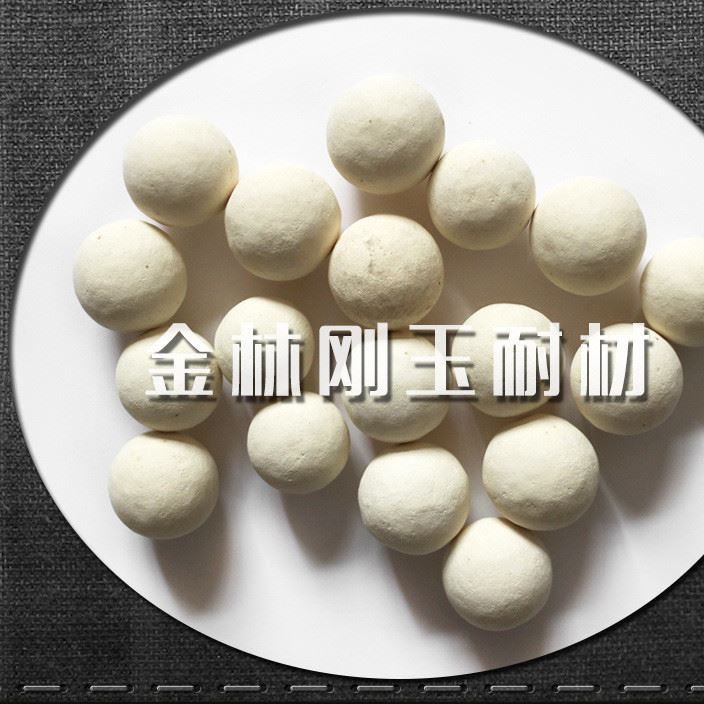

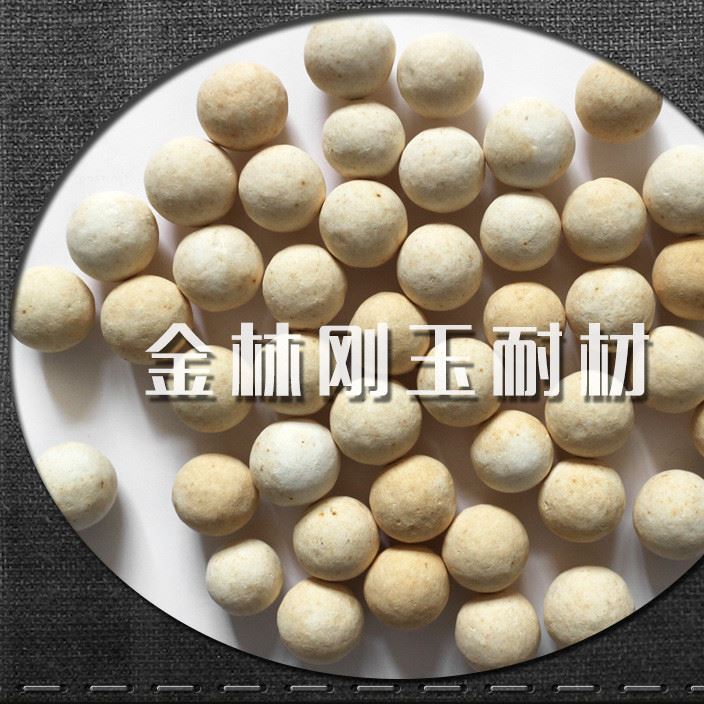

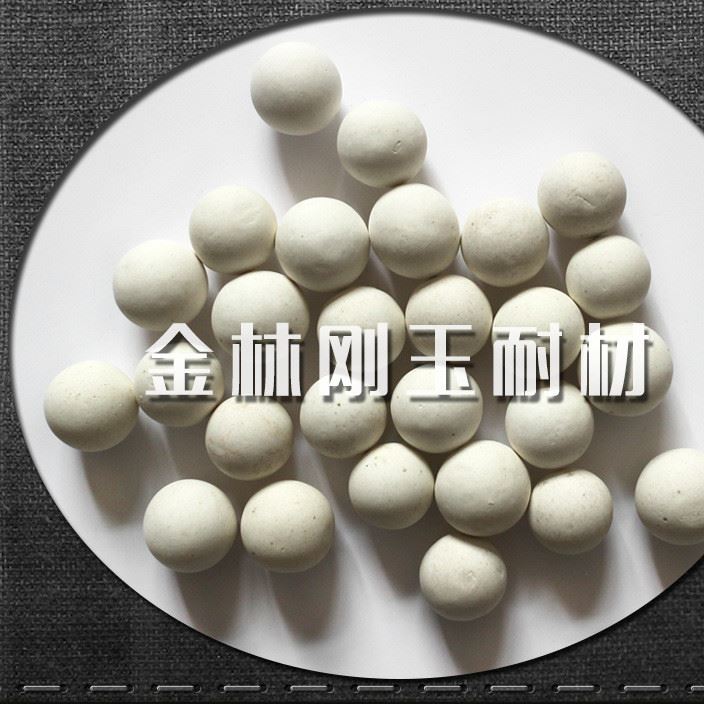

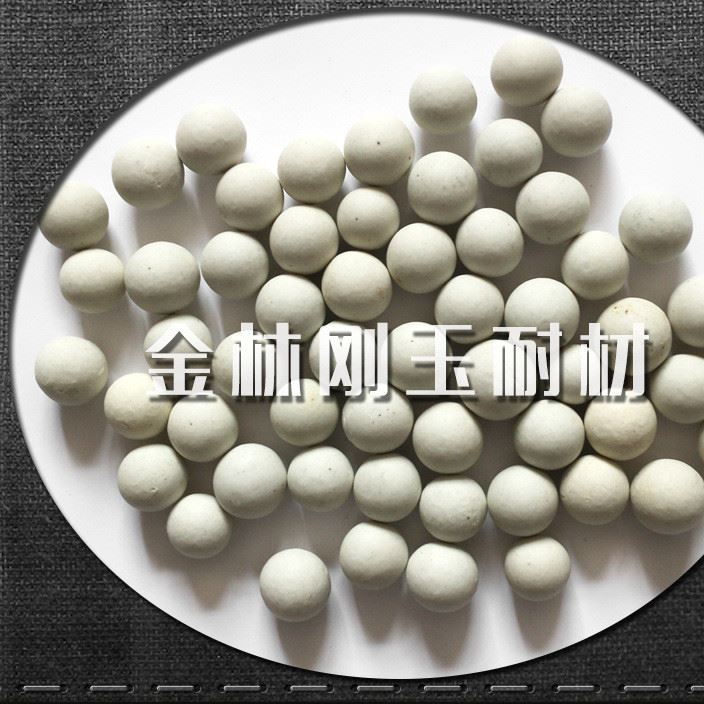

蓄热球简介

蓄热球外形呈球状,众多小球将气流分割成很小流股,气流在蓄热体中流过时形成强烈的紊流,有效的冲破了蓄热体表面的附面层,又因球径很小,传导半径小、热阻小、密度高、导热性好,故可实现蓄热式烧嘴频繁且快速换向要求。规格:3-5 5-8 8-10 15-16 16-18 18-20 20-22 22-25 25-30mm

石嘴山市金林刚玉耐火材料有限公司主营的蓄热球,具有重烧线收缩率低、高温荷重软化温度高、耐腐蚀、强度高、蓄放热量大、热震稳定性好、导热性能好、热膨胀系数小等显着特点,是优良的耐火材料。通过对煤气(高炉、转炉)和空气双预热(油类、高热值煤气等则采取助燃空气单蓄热方式),可使蓄热式加热炉达到排烟量减少20-50,排烟温度降至小于150度,产量提高 15-20,钢坯加热时间缩短50,氧化烧损降低30-50的环保节能效果。

蓄热球理化指标

性能/种类 |

空分用热瓷球 |

加热炉用蓄热球 |

Al2O3 |

20-30 |

45-75 |

SiO |

92 |

95 |

Fe2O3 |

1 |

1.5 |

热容量(J/kg.k) |

836 |

1000 |

导热系数(w/mk) |

2.6-2.9 |

|

耐热变温差( ) |

20800 |

201000 |

耐火度 |

1550 |

1750 |

抗压强度(N) |

800-1200 |

1800-3200 |

堆重(kg/m) |

1300-1400 |

1500-1600 |

蓄热球特性

1、比表面积可达到240m2/m3。

2、众多小球将气流分割成很小流股,气流在蓄热体中流过时,形成强烈的紊流,有效的冲破了蓄热体表面的附面层,又因球径小,传导半径小、热阻小、密度高、导热性好,故可实现蓄热式烧嘴频繁且快速换向要求。

3、蓄热体可利用2030次/h的换向,高温烟气流经蓄热体床层内,便可将烟气降至130左右排放。

4、高温煤气和空气流经蓄热体在相同路径内即可预热到仅比烟气温度低100左右,温度效率高达90以上。

5、因蓄热体体积十分小巧,加之小球床的流通能力强,即使积灰后阻力增加也不影响热换指标。

6、蓄热小球具有抗氧化、抗渣性强的特点。

7、陶瓷小球的更换、清洗非常方便,并可重复使用。

蓄热球用途

金林蓄热球适用于气体及非气体燃料工业炉的蓄热球燃烧系统选用,特别适用于钢铁行业蓄热式加热炉、蓄热式钢包烘烤器、空分行业空气分离设备蓄热器、有色金属行业蓄热式熔炼炉,也可用在大型锻造厂蓄热式台车炉、蓄热式电锅炉、蓄热式焚化炉等行业做蓄热载体。

蓄热球通过对煤气(高炉、转炉)和空气双预热(油类、高热值煤气等则采取助燃空气单蓄热方式),可使蓄热式加热炉达到排烟量减少20-50,排烟温度降至小于150度,产量提高 15-20,钢坯加热时间缩短50,氧化烧损降低30-50的环保节能效果。

联系方式

石嘴山市金林刚玉耐火材料有限公司

销售经理:李晴

扣扣邮箱:2105787223@qq.com

公司主页:*

地址:宁夏回族自治区石嘴山市平罗县崇岗煤炭市场

英文翻译

Introduction of regenerative ball

Regenerative ball spherical shape, so many balls will be split into small airflow flows, flow in regenerator have been out of date the formation of strong turbulence, effective broke through the accumulation of heat on the surface of the body surface boundary layer, and because the ball diameter is very small, small transmission radius, small heat resistance, high density, good thermal conductivity, which can realize regenerative burner frequent and rapid directional control requirements. Specification: 15 to 16 16 to 18 18-20 20-22 of 22-25 25 to 30 mm

Shizuishan Jin Lin corundum refractories co., LTD., production of regenerative ball, has the linear shrinkage rate is low, the high temperature and high refractoriness under load, corrosion exhaust smoke temperature dropped to less than 150 degrees, yields by 15-20, billet heating time shortened by 50, oxidation burning loss reduce 30-50 of the environmental protection and energy saving effect.

Regenerative ball features

1, the specific surface area of 240 m2 / m3.

2, many balls will be split into small airflow flows, airflow was outdated in the regenerator, the formation of strong turbulence, effective broke through the accumulation of heat on the surface of the body surface boundary layer, and because the ball diameter is small, small transmission radius, small heat resistance, high density, good thermal conductivity, which can realize regenerative burner frequent and rapid directional control requirements.

3, regenerator can use 20 30 times/h of the reversing, high temperature flue gas flowing through the regenerator in the bed, can be to flue gas emissions have fallen to about 130 .

4, high temperature gas and air flows through the regenerator in the same path can be preheated to only about 100 lower than the flue gas temperature, temperature efficiency is as high as above 90.

5, because of the heat storage volume is very small, combined with the ball the flow capacity of the bed is strong, even after heavy resistance increase does not affect the heat change index.

6, regenerative ball has the characteristics of strong oxidation resistance and slag resistance.

7, ceramic ball replacement, cleaning is very convenient, and can be reused.

Regenerative ball USES

Regenerative ball is suitable for the gas and the gas fuel industrial furnace of regenerative combustion system is chosen, especially for regenerative heating furnace of steel industry, the regenerative ladle baking equipment, air separation equipment of air separation industry regenerator regenerative furnace, non-ferrous metal industry, also used in large forging plant regenerative trolley furnace, regenerative electric boilers, the regenerative incinerator industries do regenerative heat carrier.

Regenerative ball of gas (blast furnace, converter) and the air double preheating (oil, high calorific value gas combustion air is taken, such as single heat storage mode), can make the regenerative heating furnace smoke less 20-50, exhaust smoke temperature dropped to less than 150 degrees, yields by 15-20, billet heating time shortened by 50, the oxidation burning loss reduce 30-50 of the environmental protection and energy saving effect.

contact

Shizuishan Jin Lin corundum refractories co., LTD

Sales manager: li ching

Contact phone number:

OO email: 2105787223 @qq.com

Website: *

Address: takashi shizuishan pingluo county of ningxia hui autonomous region gang coal market

产品写真

照片

联系方式

石嘴山市金林刚玉耐火材料有限公司

销售经理:李晴